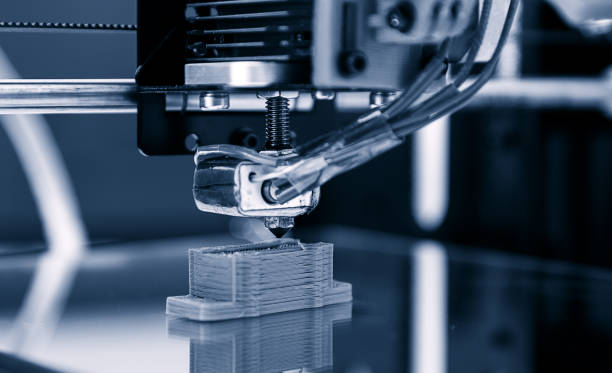

Exploring the Diverse Applications of 3D Printing Technology

In recent years, 3D printing has taken the world by storm, revolutionizing various industries and pushing the boundaries of what's possible in manufacturing, design, and innovation. From healthcare to aerospace, automotive to fashion, 3D printing technology has found its way into a multitude of applications. In this blog post, we'll delve into the exciting world of 3D printing and explore where this transformative technology is being used today.

Healthcare: Revolutionizing Medical Practice

One of the most impactful areas where 3D printing is making waves is in healthcare. The technology has opened up new possibilities for customized medical solutions.

Prosthetics and Orthopedics:

3D printing allows for the creation of custom prosthetic limbs and orthopedic implants. Traditional manufacturing methods cannot match the precision and personalization that 3D printing offers. Patients can now receive prosthetic limbs tailored to their unique needs, improving their quality of life significantly.

Dental:

The dental industry has also embraced 3D printing for the production of crowns, bridges, and even dentures. The accuracy and speed of 3D printing have transformed the way dental professionals work, reducing production time and increasing patient comfort.

Organ Transplants and Tissue Engineering:

Researchers are even exploring the possibility of 3D printing functional organs and tissues. While this field is still in its infancy, it holds great promise for the future of medicine.

Aerospace: Building the Future of Flight

Aerospace engineering is another sector where 3D printing has found extensive use. It's changing the way aircraft and spacecraft are designed and manufactured.

Lightweight Components:

3D printing allows aerospace engineers to create lightweight components that are incredibly strong and durable. This not only reduces the weight of aircraft, leading to fuel efficiency, but also enhances overall performance and safety.

Prototyping and Rapid Development:

3D printing enables rapid prototyping, which is crucial in the aerospace industry for testing and refining designs quickly and cost-effectively. This iterative process leads to more efficient and reliable final products.

Complex Geometries:

The technology enables the creation of complex geometries that were once impossible to achieve with traditional manufacturing methods. This leads to more aerodynamic and efficient designs.

Automotive: Driving Innovation with 3D Printing

In the automotive industry, 3D printing is speeding up innovation and transforming the production process.

Custom Parts:

Automakers are using 3D printing to produce custom parts for vehicles, reducing the need for large warehouses to store spare components. This results in cost savings and a more streamlined supply chain.

Prototyping:

Similar to aerospace, 3D printing facilitates rapid prototyping in the automotive sector. This allows manufacturers to test and iterate designs quickly, reducing development time.

Tooling and Manufacturing Aids:

3D printing is also used to create specialized tools and manufacturing aids, such as jigs and fixtures. These tools help improve the efficiency of assembly lines and reduce human error.

Fashion: Pushing Boundaries in Design

Fashion is all about innovation and creativity, and 3D printing is pushing the boundaries of what's possible in this industry.

Customized Clothing:

Fashion designers are using 3D printing to create customized clothing and accessories that perfectly fit an individual's body shape. This personalization is changing the way we perceive and purchase fashion.

Unique Textures and Materials:

3D printing allows designers to experiment with unique textures and materials that were previously inaccessible. From intricate lace-like patterns to sustainable materials, the possibilities are endless.

Reducing Waste:

By producing clothing on-demand and with minimal waste, 3D printing is contributing to more sustainable fashion practices, aligning with the growing demand for eco-friendly products.

Industrial: Enhancing Manufacturing Processes

Beyond specific industries, 3D printing has found its place in various industrial applications.

Jewelry Manufacturing:

The jewelry industry benefits from 3D printing's ability to create intricate and detailed designs with precision. It simplifies the production of complex jewelry pieces.

Architectural Models:

Architects and urban planners use 3D printing to create detailed architectural models, helping clients visualize projects before construction begins.

Education and Research:

3D printing has become a valuable tool in education and research. It allows students and researchers to bring their ideas to life and explore concepts in a tangible way.

Consumer: 3D Printing for Everyday Life

3D printing is also making its way into our homes, enabling individuals to become creators and designers.

Home Decor and Accessories:

People are using 3D printing to craft unique home decor items, such as vases, lampshades, and even furniture. Customization is at the forefront of this trend.

Toys and Games:

3D printing has revolutionized the toy industry, allowing parents and kids to design and create their toys. It promotes creativity and learning through play.

DIY and Repairs:

For the DIY enthusiast, 3D printing provides a valuable tool for creating replacement parts or prototypes for various projects.

In conclusion, 3D printing is not limited to a single industry or application. Its versatility, precision, and cost-effectiveness have made it a game-changer in numerous sectors, from healthcare to aerospace, automotive to fashion, and beyond.